Brand: Qingdao Zhenxiong

Production efficiency: 600 ~ 800kg / h

Equipment appearance (length × width × height): 38000 × 11000 × 4200mm

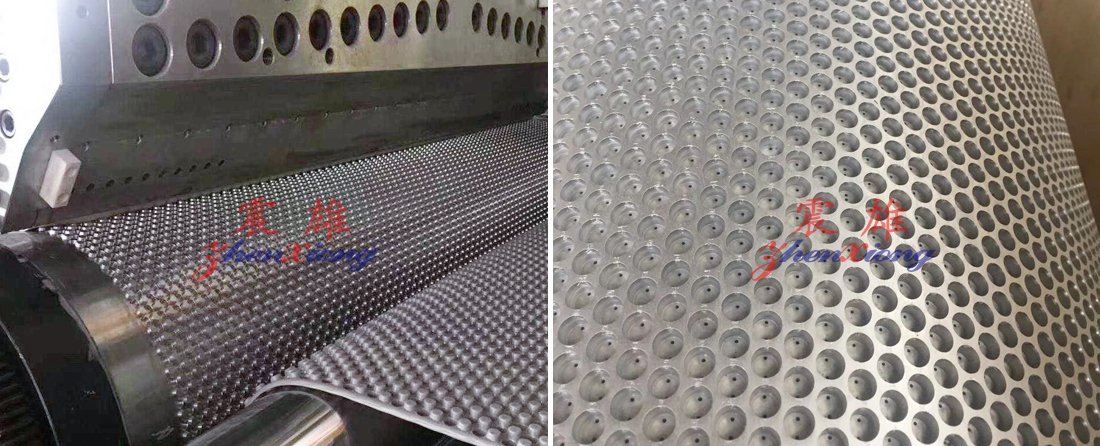

PP / PE Honeycomb Panel Production Line

Brand: Qingdao Zhenxiong

Production efficiency: 600 ~ 800kg / h

Equipment appearance (length × width × height): 38000 × 11000 × 4200mm

Product Details:

The PP/PE honeycomb board (honeycomb panel) production line adopts a process of first out board, then covering the composite type, which has the advantages of flat board surface and beautiful appearance.

Core advantage:

●The PP/PE honeycomb board (honeycomb panel) production line has added a metering pump in front of the extruder to ensure stable extrusion pressure, thereby ensuring the uniformity and consistency of the extruded board.

●The PP/PE honeycomb board (honeycomb panel) production line adopts a specially designed eight channel, four in and four out structure for the three roll rollers, ensuring uniform and consistent surface temperature of the rollers, thereby avoiding warping and deformation caused by different temperatures during product production.

●The PP/PE honeycomb board (honeycomb panel) production line adopts infrared heating for lamination, which has the advantages of strong penetration and uniform heating.

●The host of the PP/PE honeycomb board (honeycomb panel) production line adopts PLC touch screen control, which is convenient and easy to operate.

●The PP/PE honeycomb board (honeycomb panel) production line can achieve non-stop mesh replacement, saving time and reducing production costs.

●The PP/PE honeycomb board (honeycomb panel) production line mold adopts B/A A/B/A and A/B discharge methods are more conducive to material adhesion.

●The PP/PE honeycomb board (honeycomb panel) production line adopts a synchronous transmission method for upper and lower traction, which is more reliable and stable in transmission.

●The PP/PE honeycomb board (honeycomb panel) production line adopts a roller mechanical intervention method for the calibration oven, making the calibration more direct and easy to operate.

Application:

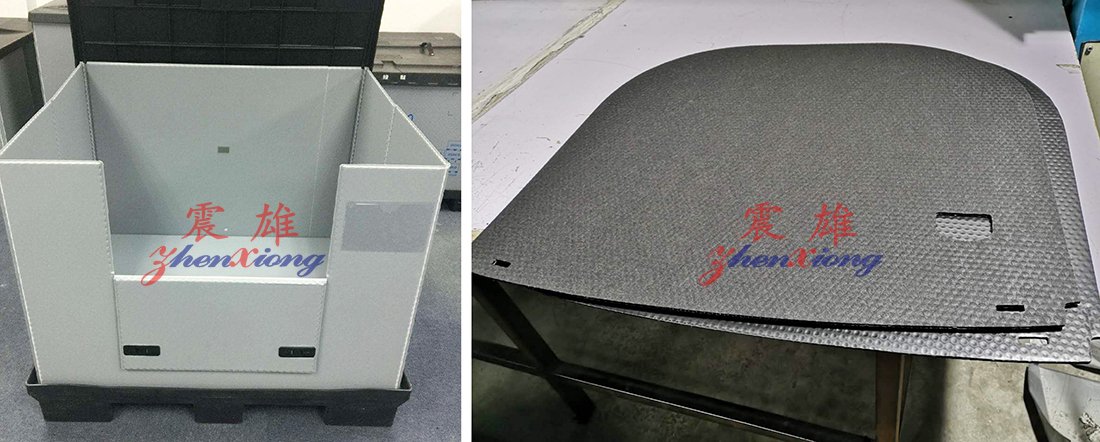

Application scope of PP/PE honeycomb board:

Transportation field: Suitable for manufacturing interior decorative panels, luggage covers, partitions, etc. for transportation vehicles such as cars, trains, and airplanes.

In the field of architectural decoration, it can be used to manufacture decorative materials for building exterior walls, partitions, ceilings, etc., playing a role in insulation, sound insulation, waterproofing, etc.

In the field of refrigerated transportation, it can be used as an insulation board for refrigerated boxes and refrigerated trucks, which can maintain the stability and insulation performance of cold air.

Other fields: It can also be applied in fields such as shipbuilding and furniture manufacturing, and can be customized according to specific needs.

Send Message:

Product Evaluation: